Over the years xtronix has delivered many custom designed products, both systems and components. xtronix custom designs removes the burdensome task of design engineering, parts procurement, assembly, testing and final qualification. We work with suppliers, often companies we actively distribute products of, to obtain the best price and delivery, leaving our customers more time to focus on their own applications and less time worrying about all the intricacies of custom designs. Solid Sealing Technology (SST) partners with us for various custom feedthrough assemblies. Here is an overview of their capabilities:

DESIGN REVIEW

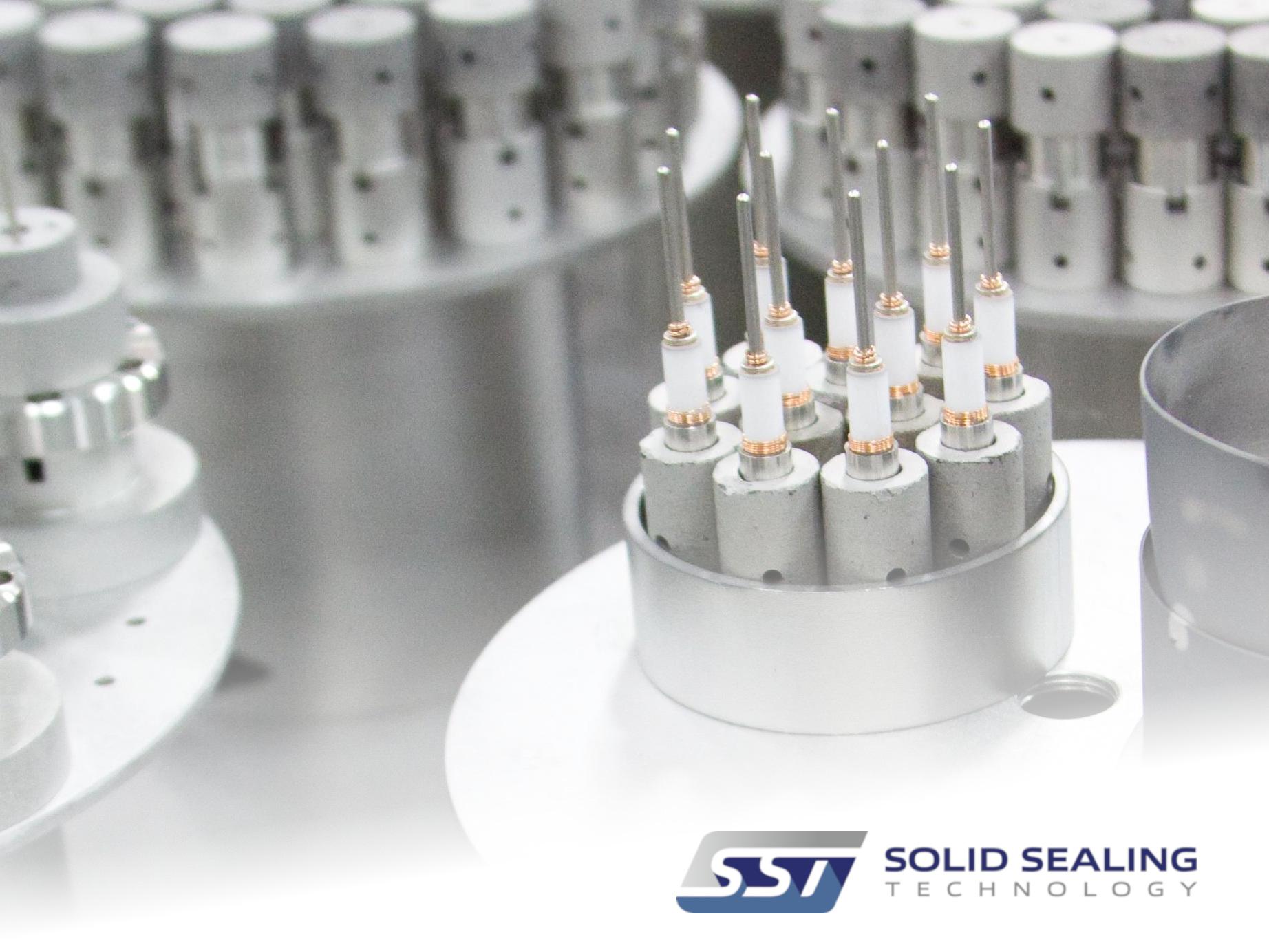

The basis of most Solid Sealing Technology products is ceramic-to-metal sealing and/or glass-ceramic sealing. The process of making your custom part(s) begins with a comprehensive review of engineering needs that ensures a complete understanding of the application’s requirements. A skilled team will define a production plan that gets you your hermetic feedthroughs and connectors quickly.

MATERIAL SOURCING

SST materials and components are sourced from world-class suppliers. Detailed documentation and specifications are available for all custom hermetic feedthroughs and connectors to ensure the materials meet your needs.

PRECISION CLEANING

All components at SST must meet strict standards and are processed through a customized cleaning system. The standardized process includes a specialty aqueous cleaner followed by a cascade DI water rinse. This cleaning process has been used and approved by key customers like Sandia National Labs and the United States' Army. The same process can be used for precision cleaning of metals, ceramics, and glass and is suitable for UHV environments. SST will ship your custom hermetic products sealed so they are ready to use out of the box.

MANUFACTURING

With your production plan in place, SST will begin manufacturing your parts. Whether you are creating a completely new custom hermetic product or modifying one of our many hermetic feedthroughs or connectors, we offer a technology suite that will meet your needs. SST offers metalizing and plating of ceramics, active metal joining, vacuum and hydrogen brazing, glass-ceramic sealing, TIG welding, spot welding, machining, and mechanical assembly.

FINAL INSPECTION & TESTING

SST verifies all critical requirements before shipping, and the customer service team will provide any product-related resources you need. SST offers vacuum-bagging and other special packaging options if needed. Parts will arrive clean and ready to use out of the box.

Calibrated tools, vision systems, and a CMM are used to verify mechanical attributes. And electrical requirements are validated with the latest electrical test equipment. SST is certified compliant to ISO9001:2015 and often works within the more stringent requirements of defense and medical customers.

- Helium Leak Detection – 100% of SST parts are leak tested before shipping. Parts are tested to a leak rate of less than 1x10^-10 atm.cc/sec

- Pressure Testing - Hydrostatic Pressure testing up to 30,000 psi

- Electrical Testing – Continuity, HiPot/DWV (Dielectric Withstanding Voltage), Megohm Resistance, Capacitance, Heat Rise Testing

- Physical Testing - Torque, Push-Pull Testing, Engagement Force Measurement

- CMM, Vision Systems, Go/No-Go thread and pin gauges, Surface Profilometer, and certified metrology equipment for inspection and analysis

- XRF Thickness Testing of Coatings & Material Verification

- Basic Thermal Testing: LN2 exposure, vacuum bakeout

- Fiber Optic Insertion Loss Testing

Click for more

For over two decades xtronix has been delivering unique custom systems, instruments, cryostats and vacuum components.

For over two decades xtronix has been delivering unique custom systems, instruments, cryostats and vacuum components.